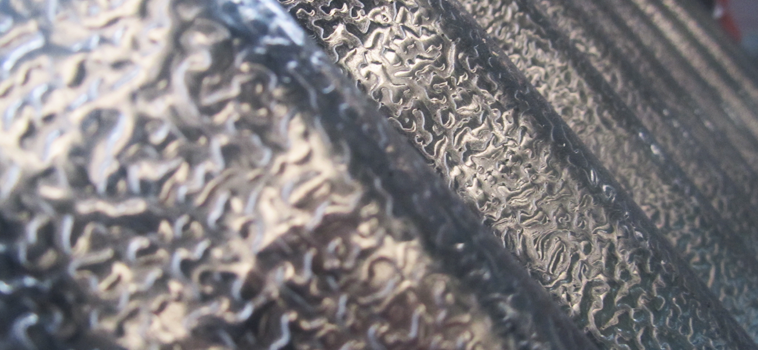

THIN ORGANIC COATINGS: BRUGAL® TOC AL

TOC or Multifunctional permanent coating specially designed for Aluminium , which find an end use in construction, appliance, automotive and electronic industries.

Characteristics

- Liquid and water borne products (Non solvents)

- Free of Volatil Organic Compounds (VOC)

- Hexavalent chromium (BRUGAL TOC 600AL Serie), Trivalent Chromium (BRUGAL TOC 300AL Serie) and Chromium free (BRUGAL TOC 000AL Serie) products are available.

- Applicable by roll-coater or chem-coater.

Performances

- Antifingerprint quality.

- Excellent corrosion resistance

Extended life of manufactured goods.

- High performances with low film weight.

Cost efficient

- Excellent formability.

Built-in Lubricity to aid post-forming processes: roll forming, profiling, avoiding the use of oils.

- Savings in oils.

Prevents scratches and marks during transport and handling.

Cleaner than oils on the shop.

- Excellent post-paintability. No post treatment required.

Brugalized aluminium steel allows end user savings and simplification of any post painting process.

- Excellent adhesion to Poliurethane foams (important performance for sandwich panels)

THIN ORGANIC COATINGS: BRUGAL® TOC AL

TOC or Multifunctional permanent coating specially designed for Aluminium , which find an end use in construction, appliance, automotive and electronic industries.

Characteristics

- Liquid and water borne products (Non solvents)

- Free of Volatil Organic Compounds (VOC)

- Hexavalent chromium (BRUGAL TOC 600AL Serie), Trivalent Chromium (BRUGAL TOC 300AL Serie) and Chromium free (BRUGAL TOC 000AL Serie) products are available.

- Applicable by roll-coater or chem-coater.

Performances

- Antifingerprint quality.

- Excellent corrosion resistance

Extended life of manufactured goods.

- High performances with low film weight.

Cost efficient

- Excellent formability.

Built-in Lubricity to aid post-forming processes: roll forming, profiling, avoiding the use of oils.

- Savings in oils.

Prevents scratches and marks during transport and handling.

Cleaner than oils on the shop.

- Excellent post-paintability. No post treatment required.

Brugalized aluminium steel allows end user savings and simplification of any post painting process.

- Excellent adhesion to Poliurethane foams (important performance for sandwich panels)

DRY LUBRICANT: BRUGAL® LUB Serie

Dry Lubricant and temporary protector. Specially designed for pressing and stamping of components for the automotive and appliance industry.

Pretreatment-Primer for Prepainted Aluminium Steel: BRUGAL® PRETREAT

Film Forming Non Rinse Pretreatmenst specially designed for Prepainted Aluminium Steel.

BACK COATS for Prepainted Aluminium Steel: BRUGALCOAT®

Non Rinse Back Coat or Primer specially designed for coil coating lines.

Characteristics

- Liquid and water borne product (Non solvents)

- Hexavalent chromium (BRUGAL COAT 600 Serie) and Cr free versions (BRUGAL COAT 000) are available.

- Applicable by roll or chem-coater.

Performances

- Improve corrosion resistance of the paint system.

- Enhances opacity of top coats.

- Excellent performances as a Backing Coat at 4 µ.

- High adhesion to PU foams.

- Constant quality.

Savings in quality control: easier and less frequent bath control requirement allowing for savings in human resource.

Savings by extreme reduction in number of rejected pieces.

Applications